Food

Grade FIBC's

SETTING THE STANDARD FOR YOUR MOST SENSITIVE PRODUCTS

Food Grade FIBC’s

Reliability, quality and confidence in supply is essential to our customers, which is why our food grade bulk bags are manufactured with 100% virgin polypropylene resin under food standards such as British Retail Consortium (BRC), American Institute of Baking (AIB), FSSC 22000, SQF and IFS certifications that meet the strict requirements set forth by both the food/pharmaceutical sectors and the GFSI (Global Food Safety Initiative).

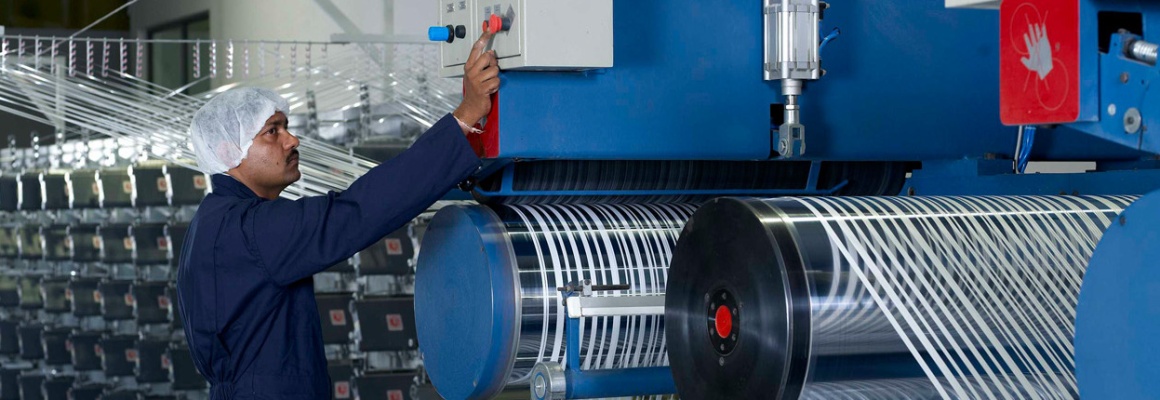

Produced in a complete clean room environment with filtered ventilation, dust removal systems and GI stands, food-grade bulk bags are manufactured to the highest standards with state-of-the-art ultrasonic cutting equipment. At the forefront of innovation, our partner facilities can tailor almost every element of your bulk bag construction, including filling/discharge spouts, bag shape, liners, baffles, safe weight limit, fabric and loops.

With decades in FIBC supply and regular audits from blue-chip food companies, our partner facilities procedures, quality control processes, hygiene standards and traceability systems are globally renowned.

To Find Out More About Our Food Grade FIBC'S

Hygiene

Audited by major blue-chip companies, our partner facilities produce only the best quality food grade bulk bags, using 100% virgin grade resin, as per FDA standards.

Traceability

State of the art traceability systems allows for quick and clear location of production units, mitigating errors and allowing for easy diagnosis of error patterns.

Innovation

Highly technical liners including 7-layer gas flushing barrier and aluminium liners. Seam-reducing constructions for fine powder products.

Experience

Decades supplying the food industry with food grade bulk bags including high dairy, milling, seeds and pulses, sugars, pet feed and confectionary sectors, see our case studies

Food Grade FIBC Buyer’s Guide

Click the button below to download our Food Grade FIBC Buyer’s Guide to get access to our manufacturing comparison chart, a handy tool for buyers to show how we go above and beyond to ensure our customers food grade bulk bags are produced to the highest quality under the most stringent conditions.

Highly Accredited Facilities

Produced in elite partner facilities, our food grade bulk bags meet the strict requirements set forth by both the food/pharmaceutical sectors and GFSI recognised bodies; BRC (British Retail Consortium), SQF (Safe Quality food Institute), AIB (American Institute of Bakers), FSSC22000 and IFS (International Featured Standards). Find out more about them by clicking on the logos.

To Find Out More About Our Food Grade FIBC'S

Case Studies

Food-Grade FIBC’s for Mondelez

Mondelez, are a multinational confectionery, food, and beverage company who employ 107,000 people around the world. Manufacturing chocolate, biscuits, gum, confectionery and powdered beverages. Mondelez’s portfolio includes several billion pound brands such as Belvita, Chip Ahoy! Oreo, Ritz, Milka, Terry’s, Tolberone, Cadbury’s, Halls and Fry’s.