Maxi Cube FIBC (Q Bag)

The Maxi-Cube FIBC, also known as the Q bag or baffle bag, is designed to prevent deformation, ensuring that your FIBC maintains a square or rectangular shape when filled.

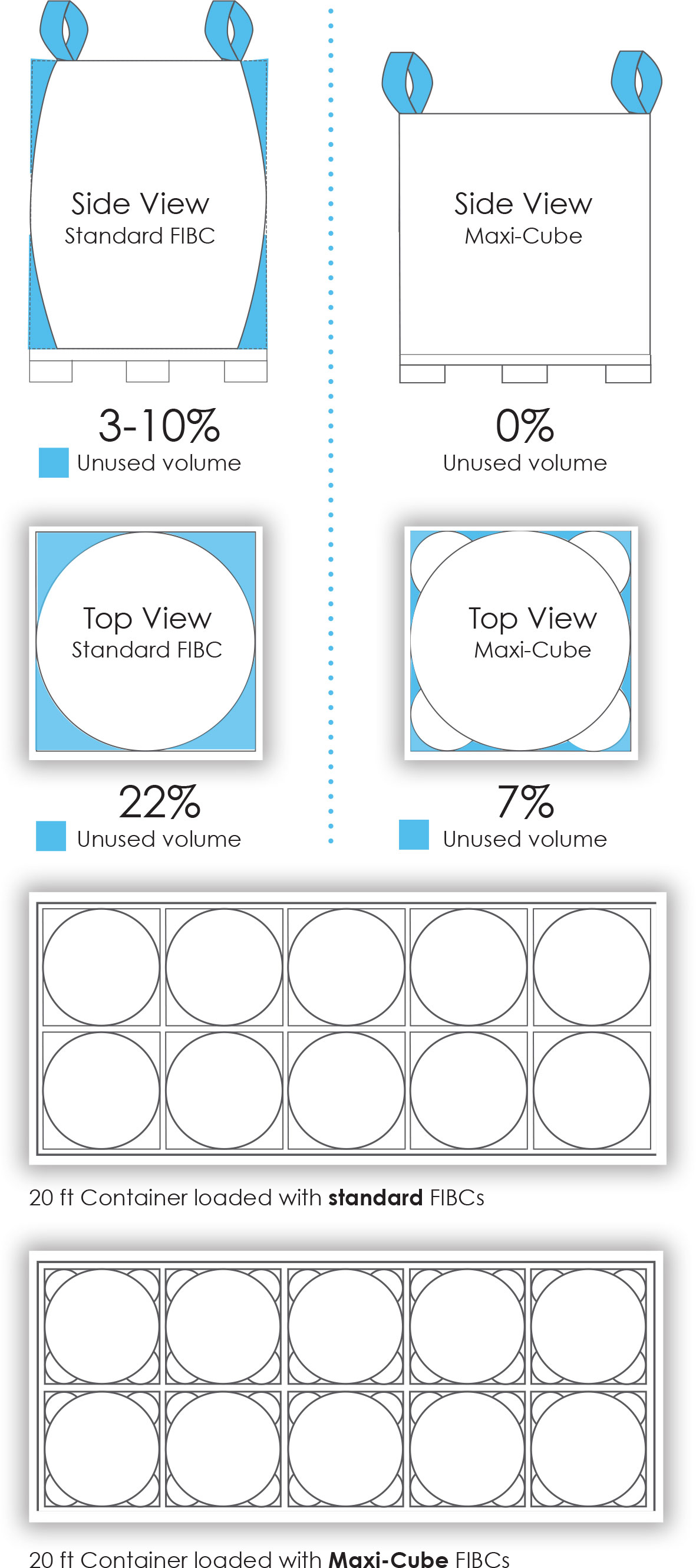

There are several benefits to using this baffle bag design, including optimising space, as the Maxi Cube can allow for up to +30% more product/weight per pack in comparison to a standard FIBC, which in turn can lead to significant savings in the transport, storage and handling of free-flowing powder, granule, pellet or flake when sent in containers, lorries or by rail.

The internal construction of the Maxi-Cube is very stable as the interior corner pillars allow the Q bag to fill into a cube shape which fits the pallet size used:

- CP1 - 100 x 120cm

- CP9 - 114 x 114cm

- EURO - 80 x 120cm

A standard FIBC will tend to go more circular and can be unstable if the product packed is quite fluid-like or the bag is tall.

A number of baffle options are available, each offering different properties for your product and filling operation:

Standard Baffle: Woven PP panels with windows to allow for the free flowing of product during the fill and discharge of the baffle bag

Net Baffle: Woven PP yarn sewn into the corner allows for an even higher increased flow of product