Form Fill & Seal

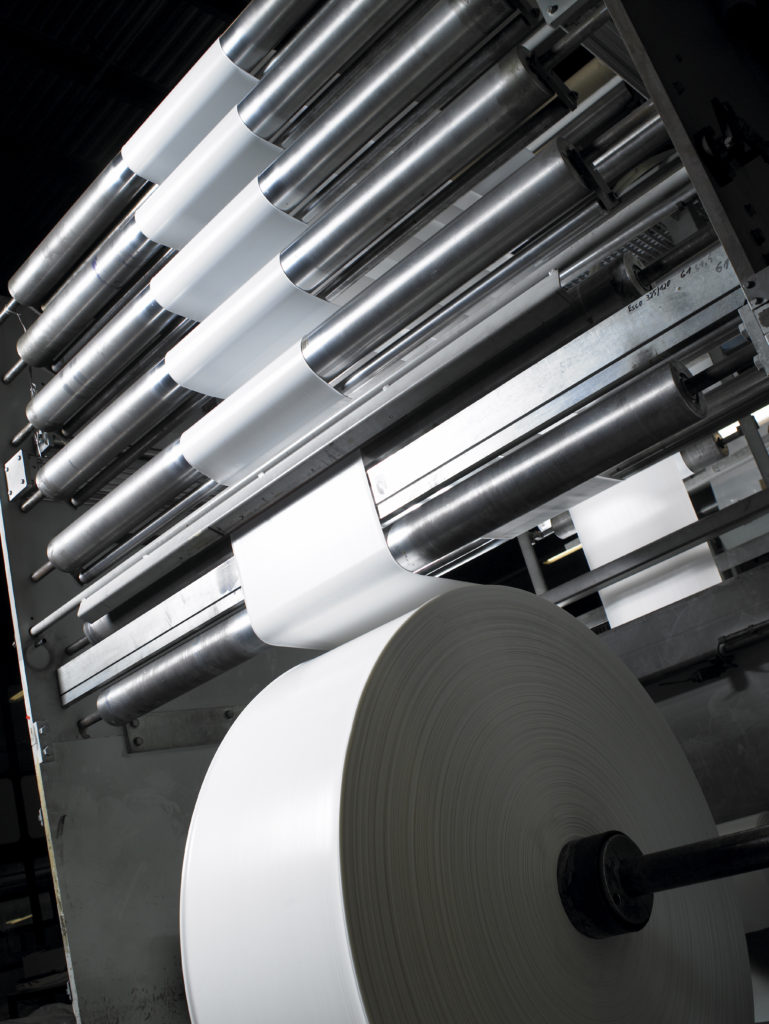

Form, Fill, and Seal (FFS) films are the most efficient solution for automated processes of bagging bulk materials. Optimal run-ability allows the highest efficiency of the filling process. High-strength materials provide optimal storage and transportation properties. Various de-aeration options, premium 10-colour print and food compliance are available.

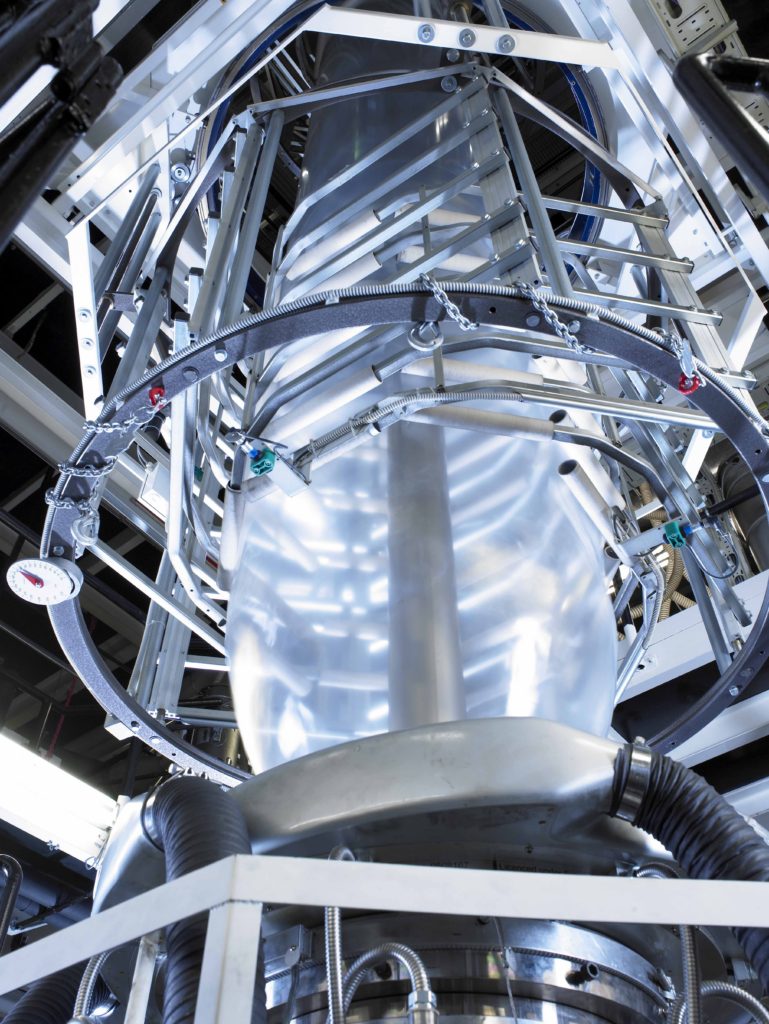

Lower capital investment outlay has meant that film on the reel is increasingly showing significant cost savings for a completed pack in comparison with open mouth sacks and other forms of packaging. In recognition of this, investment has been made in the latest extrusion so that we can offer the best technical and competitive solutions for your packaging needs.

With our expertise in plastics, we have developed a range of films that perform consistently in both main formats; tubular film (straight extrusion or back seam) and flat sheet film.

State-of-the-art extrusion ensures that we can offer technical films for improved performance on the packer, when stored and during transportation. Lower gauge films that put us at the forefront of the market allow us to tailor the product to your needs, meaning higher packing speeds, lower inventory costs, a reduced finished pack cost.

Additional Options

![]()

Anti-Slip

Additional coating for a

particularly non-slip surface

![]()

Barrier+

Enhanced water barrier for

particularly hydrophilic goods

![]()

Tight+

Additional longitudinal seam

to protect particularly fine powder

![]()

Seal+

Improved sealing seam for

highly contaminated weld areas

contact us:

Design your own packaging!

Using the online configurator

you can design and modify your own Plastic Sack. Get in touch today and we'll send you a Free Link to design your own bestseller with the Online Configurator (best design)

CASE STUDY

FFS (Form, Fill and Seal) tubing film for Hanson

Hanson is part of the Heidelberg Cement Group, which employs 57,000 people across five continents. Heidelberg Cement is the global leader in aggregates and has leading positions in cement, concrete and heavy building products.

Hanson’s UK business is split into three business lines – quarry products, building products and cement – which together operate over 350 manufacturing sites and employ more than 6,000 people.

The Packed Products division had a major CAPEX project to move some branded lines from paper-based packaging to plastic. This required new packing equipment and the development of a plastic pack that would...