U.N. GRADE FIBC'S

UN Grade FIBC's must align with United Nations regulations & framework for transporting hazardous goods by sea, rail and road. When you work with Rosenflex, you are ensuring that your UN bulk bags are designed, tested and manufactured with full adherence to UN Regulations, with testing completed both in the manufacturing facility and then repeated in an independent testing facility to ensure official certification.

UN FIBC's are tested with a wide variety of safe working loads (SWL) and come in various formats and models to suit even the most demanding conditions.

Testing methods for UN-approved bulk bags include:

- Lift Assessment– Filled to six times its maximum load, the UN FIBC is then lifted off the surface with hydraulics to ensure the safe working load weight.

- Tear Test– The UN bulk bag is then filled to the maximum load before the adjudicator makes a small tear (100mm). The bag is then filled to twice its maximum capacity before being rested for a short period. Finally, the bulk bag is suspended with its safe working load for a minimum of five minutes.

- Drop Test – The bulk bag is then filled to its maximum load before being lifted to 80-120cm before being dropped in an upright position

- Stack Test – UN FIBC’s are loaded 1.8 times their maximum weights before being stacked.

- Topple Test – Similar to the drop test, the big bag is toppled from 80-120cm hitting the surface on its side.

- Recovery Test – Once the topple test is complete; the bulk bag is lifted into an upright position.

CONTACT US

UN REGULATIONS

UN recommendations on the transport of dangerous goods (Orange Book)

| IMDG | Chapter 6.5 | Transport by sea |

| ADR | Annex A 6 | Transport by road |

| RID | Annex A VI | Transport by rail |

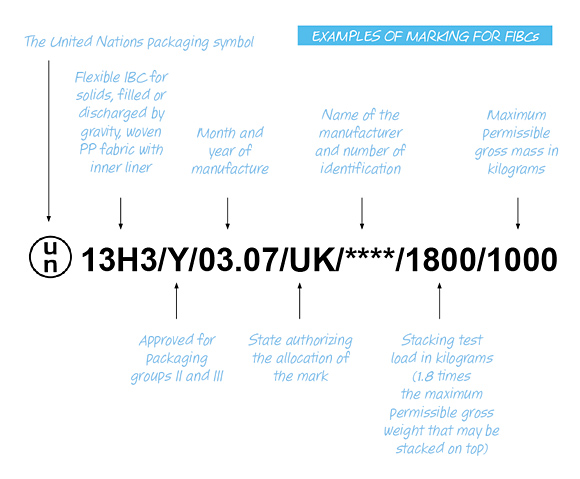

UN CODE FOR THE TYPE OF FIBC

| 13 | Flexible IBC for solids, filled or discharged by gravity (liquids and solids under pressure [>0.1 bar] are not permitted) |

| H1 | Woven PP fabric without coating or inner liner |

| H2 | Woven PP fabric, coated |

| H3 | Woven PP fabric with inner liner |

| H4 | Woven PP fabric, coated and with inner liner |

| Y | Flexible IBC approved for packaging groups II and III |

| Z | Flexible IBC approved for packaging groups III |